How To Repair a Rusted Metro Frame

by Rick

The front end of all Geo Metros will eventually rust out unless the owner is very active in maintaining the area to protect from rust. To protect the suspension from rusting out it needs to be coated with rust proofing or even oiling it will keep rust away. If you are the owner of a Metro that is not in good shape in my opinion it is possible to repair the car without having to junk it. This is how I would do it if I was going to repair it.

In order to do the repair you need to be a good welder or have access to one. A good source for very good quality work in the United States is to take the car to a local vocational school. They will usually do the work for the cost of materials and a small ~$25 donation to the school. Just make sure to talk to the welding shop teacher and not the automotive shop. To get the car ready there is a lot that needs to be removed. The stuff I list here is what I think needs removed, depending on the repair you might need more or less removed.

- Take the wheels off

- Take the Tie rods out, or the entire steering rack, whatever you think is easier. This might be able to remain depending on the repair.

- Remove the battery and battery tray.

- Remove the air filter hose and the air filter.

- Take the front pulley off the engine and the alternator.

- The axle shafts probably will need removed but depending on the repair they might be able to stay.

- Pull back the carpet away from the front. Just lay it on the seats to keep it from catching on fire from the welding being done on the opposite side of the floor pan.

This should give you access to the frame areas. If you only need one side repaired you could do just one part but while the car is being repaired doing both sides would be wise.

If it is still solid and not already rusted out enough to let the control arm move fabricate a temporary brace to hold the arm in position. Just tack weld it up to the frame or anywhere handy. I have included the pages in the factory service manual showing measurements so it can be double checked to make sure the car stays square. Click on the pictures to enlarge them.

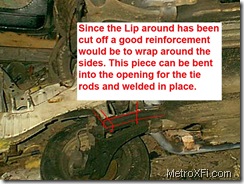

Take the bolts out of the bottom of the suspension mount so the forward part of the A-arm is free. Now cut off the lip around the mount area. This lip is where the factory joined the different sections together. It is probably not actually doing much more than holding rust now.

Take the bolts out of the bottom of the suspension mount so the forward part of the A-arm is free. Now cut off the lip around the mount area. This lip is where the factory joined the different sections together. It is probably not actually doing much more than holding rust now.

The frame rails are made of thin metal as well as the firewall. Welding to these will not be as strong so avoid it if possible. If possible just weld about halfway up the mount. The metal should still be in good shape in that area and have all the strength needed to support the mount.

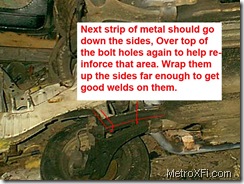

I would start by cutting a strip a foot or so long by about 2 inches wide and go across the bottom 2 bolt holes wrapping it up to the front. Then take a strip and go across from the wheel area down under the mount catching the front bolt mount and up the other side halfway again. Do the same thing for the rear bolt by starting on the wheel side but the inner part will be tighter and have to be a bit more careful fitting it.

Once the bolt holes have plenty of metal supporting them they can be drilled back out or if the bolts broke off they can be left covered and the mount just welded onto them. I would then add another layer of metal covering all of lower part of the suspension. If the bracket that holds the front mount sits a bit lower than factory it is not going to really change anything about how the car rides or handles so don't worry about putting two or three layers of metal over the factory stuff. Also once the main parts are welded up it is probably a good idea to keep adding metal and building up anything that looks weak. It is better to put more on it than not enough.

I would probably use 14ga sheet metal to repair the car. If you want it to last longer than the rest of the car then you can use something like 10ga but it will be a lot harder to weld up to the factory parts. If you don't think your welding skills are up to it find a shop you trust and ask them about having the work done. On my pictures you can ignore the primer gray tubing shown, I was in the process of building my tube chassis car and used those pictures to explain the process. But with those pictures and looking at your car it should be easy to figure out what needs done to repair the car. Just remember you are not building a race car so trying to save weight on this repair will end up with a weaker repair than you otherwise would so use good metal and don't be afraid to add more than you think you need to do the job.

Also if you think you are not up to the repair you should find someone who thinks they can repair it properly. Every car will have rust in slightly different areas so the repairs might be different than I have suggested here. If you kill your car don't blame me, I am just offering my opinion on what is needed to repair them.